Click Bond has supported missions of consequence for nearly four decades.

By Jessica Santina

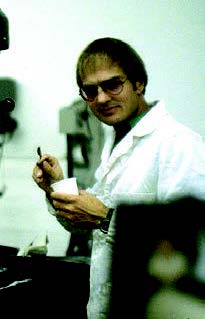

In 1987, a Carson City-based physicist, engineer, and pilot named Charlie Hutter asked the two little words that have launched so many innovations throughout history: “What if?”

It all started with his own airplane. Charlie came out to the tarmac one day to discover that the holes for rivets — small, headed pins used to hold fasteners and metal parts together — in the plane’s fuel tank were leaking fuel. Charlie, who owned a research and development firm with his brother, Peter, was a natural innovator and problem-solver. He immediately began to consider how he could plug the already-oversized holes surrounding the rivets to stop the leak in its tracks. After all, why add more holes to an aircraft? Then he remembered something he’d learned from his orthopedic surgeon father about adhesives that could cure in the presence of fluids.

What if he could use adhesives to repair the leak? Rather than perpetuating the problem by adding bigger and bigger rivets or drilling more holes, perhaps he could seal the hole permanently.

On a napkin, Charlie sketched out his idea for a thin, concave aluminum disc with a fixture on the underside. The user would apply adhesive around the edge, properly position the patch over the leak, and then push down until they heard a “click.” Once activated, the fixture would apply positive pressure, holding the patch against the airplane’s surface while the adhesive cures, thereby sealing the leak.

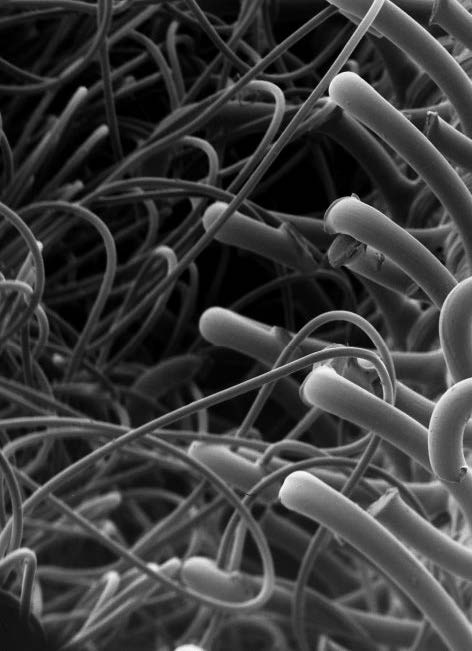

That invention, the Click Patch, launched the Click Bond product line and stimulated further development, leading to dozens of global patents and a diverse line of more than 5,000 adhesive-bonded assembly solutions, available worldwide. Today, Click Bond is headquartered in Carson City, with an additional facility in Watertown, Connecticut, and now employs more than 500 Click Bonders. In its nearly 40-year history, Click Bond, which is still owned by the Hutter family, has earned a reputation as a premier assembly-solutions provider. In addition to the Click Patch, its product line now includes structural hardware, systems installation fasteners, adhesives, and tools, as well as XR-enabled digital solutions that streamline the assembly process. All fasteners are installed using Click Bond’s signature adhesive bonding, which not only eliminates the need for rivets — and the additional drilling of holes in a structure to accommodate them — but also eliminates their associated weight and potential corrosion.

Click Bond’s products have been trusted on some of the world’s most sophisticated aerospace, defense, naval, marine, automotive, space-exploration, and industrial programs, including the F-22 and F-35 fighter jets, the Mars Curiosity Rover, NASA’s Artemis, Formula 1 cars, Vertical Aerospace’s VX4 autonomous electric vehicle and much more. “We pride ourselves on partnering with our customers for their programs’ entire lifecycles, from customer-driven design, through manufacture and sustainment,” says Karl Hutter, Charlie’s son, who now serves as Click Bond’s Chief Executive Officer. “Just as my father exemplified back in 1987, our mission is to expand the possible and deliver enduring value to missions of consequence around the world and beyond.”

For details about Click Bond’s history, its products, or its people, visit www.clickbond.com.